Need rear collection capabilities on your lawn tractor? The X350R adds that feature to our affordable no-frills entry into the lawn tractor segment. You’ll also appreciate the clean, car-style display, ergonomically laid-out controls, and the easy-to-operate Twin Touch™ hydrostatic transmission control pedals. Choose from a range of mowing decks and adapt your X350R to your specific requirements

Features

Engine is smooth running and reliable with V-twin air-cooled design

14.1-kW at 3100 rpm V-twin engine

14.1-kW at 3100 rpm V-twin engineThe tractor is powered by an iTorque power system, a combination of engine features, and an exclusive hood design that provides superior lugging ability, even cooling, and durability.

A large 726-cc (44.3-cu in.), 14.1-kW engine at 3100 rpm has plenty of power and torque for superior performance. The larger, more powerful engine also allows the engine to be operated at a lower 3100-rpm speed for quieter operation.

Key engine features include:

- 14.1 kW at 3100 rpm

- Large 726-cc (44.3-cu in.) displacement

- Quality features include:

- Cast-iron cylinder liner

- Overhead valve

- Full-pressure lubrication

- Replaceable oil filter

- Dual-stage air cleaner

- V-twin design:

- Excellent power and performance

- Easy starts

- Smooth operation

FLYWHEEL ALTERNATOR

A flywheel alternator provides plenty of capacity to quickly recharge the battery and power electrical equipment, such as lights or a sprayer:

- 12-amp charging capacity

- Regulated to keep the battery at full charge without risk of overcharging

FUEL TANK HAS LARGE, CONVENIENTLY LOCATED FILL OPENING

Large fuel-fill opening

Large fuel-fill openingLarge, 7.6-cm (3-in.) diameter fuel tank filler opening makes adding fuel easy:

- Located on the left fender

- Helps eliminate spillage

- 7.6-L (2-U.S. gal.) capacity

- Low fuel light on dash warns the operator when fuel level is getting low

107-cm (42-in.) Rear-Discharge Rear-Collect Mower Deck cuts clean

107-cm (42-in.) Rear-Discharge Mower Deck

107-cm (42-in.) Rear-Discharge Mower Deck X350R 107-cm (42-in.) Mower Deck

X350R 107-cm (42-in.) Mower DeckThe innovative design of the 107-cm (42-in.) Edge™ Rear-Discharge Deck combines the best features for reliability and superior performance when mowing, collecting, and mulching grass and leaves:

- The mower deck is stamped from 11-gauge, 3-mm (0.120-in.) steel to provide smooth contours for a quality appearance and excellent performance.

- Easy to install or remove mulch plug is included as standard equipment.

- The included AM147289 blades provide optimal collection/rear discharge and good mulching results in many conditions. For optimal mulching, AM140332 mulching blades are available.

- With no side-discharge chute, the mower can trim on either side for mowing efficiency and convenience.

- A smaller storage area requirement is an additional benefit.

- A standard V-belt and non-timed blade design gives superior reliability and trouble-free operation.

- Offset mower blades permit blade overlap with the use of a standard V-belt drive.

- The blades cut cleanly without being able to contact each other.

- A heavy-duty V-belt and large spring-loaded idler pulley transfer power to the mower blades efficiently and reliably.

- Three mower wheels help level the mowing job and reduce the chance of scalping the lawn.

- Cut-height increments of 0.64 cm (0.25 in.) allow for operating the mower at the optimum cutting height.

- A quick-adjust deck-leveling system is provided to make keeping the deck properly adjusted easy.

Contoured deck and discharge blade, 92-cm (36-in.) mower for X135R shown

Contoured deck and discharge blade, 92-cm (36-in.) mower for X135R shownThe mower deck is contoured and free of obstructions to ensure optimum cutting and bagging performance:

- Grass clippings flow smoothly around the deck and up the chute into the hopper.

- Clipping buildup is minimized to ensure continued high-performance and easy cleanup.

- Special discharge blades (standard equipment) have a large wing to propel grass clippings up the chute and into the hopper.

- Mower fills and packs the 300-L hopper with a large volume of grass clippings and/or leaves.

STANDARD MULCH PLUG

Standard mulch plug

Standard mulch plugMulch plug easily installs in place of hopper:

- A mulch plug is included with the model year 2017 and later X350R as standard equipment (SN 20,001-).

- Mulch plug is ideal for times when collecting grass clippings and leaves is not desired. The rear hopper can be easily removed and the mulch plug installed.

- Plug closes off opening on bottom of deck so material cannot enter the chute.

- The included AM147289 blades provide optimal bagging and rear discharge performance and good mulching results in many conditions.

- For optimal mulching, AM140332 mulching blades are available.

Wash port

Wash port Hose-end adapter example shown can be purchased locally - not standard equipment

Hose-end adapter example shown can be purchased locally - not standard equipmentWash ports are provided on each side of the mower deck. They can be used to supply water to the underside of the deck so it can be easily cleaned after use:

- Wash ports are designed for hose quick-connect fitting.

- Connect hose to the wash port on one side of the mower at a time and operate the mower to clean.

- Using the wash ports cleans bottom of deck and chute.

- Wash ports work best if used immediately after the mowing job is completed.

- Operating the mower deck while the water is running removes grass clippings.

- Use of the wash ports prevents buildup of material from affecting performance the next time the mower is used.

A hose-end adapter for the appropriate water hose to be used can be purchased locally for connection to the wash ports.

Optional rear deflector

Optional rear deflector Optional rear deflector in operation

Optional rear deflector in operationOptional rear deflector (BM25065) easily installs in place of hopper:

- No tools required for installation

- Deflects clippings in an even pattern behind the tractor

Rear hopper has large capacity and is easy to empty

Hopper easily emptied from operator seat

Hopper easily emptied from operator seat Long handle gives good leverage

Long handle gives good leverage Durable 300-L (8.5-bu) hopper empties completely

Durable 300-L (8.5-bu) hopper empties completelyThe innovative design of the rear hopper sets a high standard for collecting systems:

- Hopper is constructed of durable fabric for flexibility, where needed.

HOPPER SHIPPING

Hopper is nested in tractor for efficient shipping

Hopper is nested in tractor for efficient shipping Large-capacity hopper

Large-capacity hopper- Minimizes shipping cost

- No extra carton material, which reduces disposal cost

Hopper is made of durable materials and sealed to keep dust away from the operator.

Steering is low-effort sector and pinion system

High-quality steering system for easy operation

High-quality steering system for easy operation X350R is designed for easy turns

X350R is designed for easy turnsA heavy-duty sector and pinion steering system with quality bearings provides easy and precise control for the life of the tractor:

- Tight turning radius of 42 cm (16.5 in.) provides good maneuverability.

- Easy steering promotes mowing efficiency and operator comfort.

EASY STEERING

Easy steering is important to give the operator an enjoyable mowing experience:

- Larger, 36-cm (14-in.) diameter steering wheel gives good leverage for easy turns.

- Larger sector gear gives improved (increased) steering ratio.

- Higher steering ratio results in less effort to turn the wheel.

- Ball-joints on both ends of the steering tie rod and drag link maintain accurate steering longer.

- Long steering drag link improves mechanical advantage of the steering system through the full range of motion.

- Sector gear pivots on a shaft rather than a bushing.

- This ensures proper gear mesh and eliminates binding to result in easier steering.

- Greaseable front steering spindles reduce friction and improves wear through time.

Integrated hydrostatic transaxle is efficient

Kanzaki® K46 transaxle

Kanzaki® K46 transaxle

The Tuff Torq® hydrostatic transaxle encloses the hydrostatic pump and motor rotator groups in the same housing with the differential and axle housings:

- This very efficient design reduces the number of sealing surfaces and minimizes potential for leakage.

- The transaxle is essentially the same as the one used in the X300 Tractor; however, it is reversed, and the drive linkage is unique to work with the rear-discharge system.

When combined with the foot controls, the hydrostatic transmission functions similarly to an automatic transmission in an automobile, so the term automatic is often used to describe it:

- Use of the latest valve designs has significantly reduced the sound level.

- Large pump and motor rotating groups ensure efficient operation and long life.

FREE-WHEELING VALVE

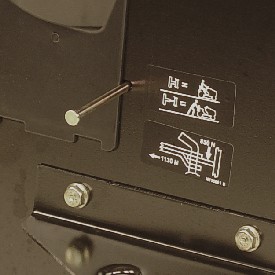

Convenient free-wheeling valve

Convenient free-wheeling valve

The free-wheeling valve control is located near the tractor rear hitch plate for good visibility and easy operation.

Kanzaki and Tuff Torq are trademarks of Kanzaki Kokyukoki Mfg. Co., Ltd.

Controls are convenient and easy to find

Operator station

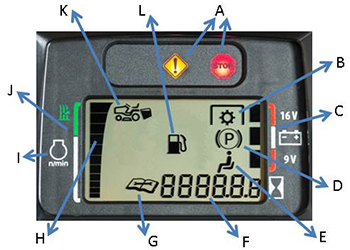

Operator station Display panel

Display panelThe contoured dash has clean, attractive styling and ergonomic controls for easy use:

- Controls are color-coded for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The power take-off (PTO) switch allows the operator to get fingers underneath it, like a T-handle, to pull up for easy activation.

- The reverse implement option (RIO) switch is an easy to see and use yellow button.

- To simplify snow blower operation, RIO can be activated with the same hand that lifts or latches the snow blower.

- The latch control for foot lift and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

- Functional design of the throttle and choke controls provides good appearance and a comfortable feel.

| ||||

|

A — Caution / stop | G — Service | |||

| B — Power take-off (PTO) | H —Engine speed | |||

| C — Battery charge status | I — Engine speed symbol | |||

| D — Park brake | J —Best cut range | |||

| E — Operator presence | K —Material collection system (MCS) | |||

| F — Hour meter | L - Low fuel | |||

Display has the look and feel of a modern automobile. A power-up sequence cycles lights and gauges to indicate they are working:

- Display features dark-cockpit design to minimize operator distractions.

- Display is back lit for night visibility.

- Night visibility is especially useful with snow blower use.

- When the hopper is full, the hopper-full light comes on and the tractor power take-off (PTO) automatically shuts off.

- Hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Low fuel light provides the operator with a noticeable warning when low on fuel.

- A tachometer graphically displays engine speed.

- Target-zone graphics inform the operator of the engine speed range to use for best cut quality.

- An indicator tells the operator when the PTO is operating.

- Bright caution and stop lights capture the operator's attention when important information is on the instrument cluster.

- Damage can be prevented and repair costs reduced by addressing problems early.

- Operators are advised of what the problem is if they attempt to operate the mower with unsatisfied PTO, seat, or park brake interlocks.

- The indicators are also useful to identify the reasons the PTO or engine may have shut off when an interlock is unsatisfied.

- Operators are advised if battery voltage is low, normal, or excessive.

- The service indicator light illuminates to indicate a diagnostic error code is stored.

- On-board diagnostics provides trouble codes for use by trained technicians.

- For example, a technician will be able to test switch functionality and circuit continuity without tools.

FOOT-PEDAL LIFT SYSTEM

Foot-pedal lift system

Foot-pedal lift systemPushing with the foot to raise the mower or implement is less strenuous for many operators:

- The easy-to-use raised position lock operates similarly to the park brake lock.

- The foot pedal is out of the way and not likely to catch on bushes and tree limbs when mowing.

- The mower deck returns to same preset height each time it is lowered.

- A lift-assist spring is provided to minimize lift effort.

- An optional BM24810 supplemental lift-assist spring kit (X350R) is required for snow blower use.

- The mower will not be inadvertently locked in the raised position when mowing through ditches.

- When installing or removing a mower or front equipment raised by the foot lift system, spring tension may be removed from the connection points by pulling rearward on the lift pedal and raising the lift latch to hold the pedal in the rearward position.

TWIN TOUCH™ FOOT CONTROL IS EASY TO USE AND HAS CRUISE CONTROL

Twin Touch foot control

Twin Touch foot control Cruise-control button on the dashboard

Cruise-control button on the dashboardTwin Touch foot pedals control the speed and direction of travel:

- Automotive-type accelerator control ensures easy operation.

- Operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

CRUISE CONTROL

Cruise control is standard equipment:

- To engage, push the cruise button and hold until the foot is removed from the forward pedal.

- For emergency stop, the cruise control can be released by pushing on the brake pedal or the forward pedal.

MOWER DECK HEIGHT ADJUSTMENT

Mower deck height adjustment

Mower deck height adjustmentRotary dial knob makes adjusting mower cut height quick and easy:

- Provides mower cut heights in 0.6-cm (0.25-in.) increments from 2.5 to 10.2 cm (1 to 4.0 in.)

- Mower deck returns to same preset height each time it is lowered

- Onboard deck-leveling gauge and Exact Adjust tool conveniently located in the storage compartment under the seat

- Used in conjunction with Exact Adjust ports for easy and accurate leveling of the mower deck for optimum mowing performance

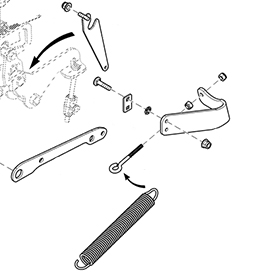

OPTIONAL SUPPLEMENTAL LIFT-ASSIST SPRING

Supplemental lift-assist spring kit parts

Supplemental lift-assist spring kit partsAn optional supplemental lift-assist spring is available:

- Required for snow blower use.

PARKING BRAKE CONTROL

Parking brake

Parking brakeDepressing brake pedal applies internal wet-disk brakes (increased durability and longer life) for safe stopping.

Parking brake control is conveniently located for easy access; holds brake pedal securely in locked position.

ELECTRIC PTO CLUTCH IS EASY AND CONVENIENT TO USE

Electric PTO switch

Electric PTO switchA heavy-duty electric PTO clutch is controlled by a convenient dash-mounted switch.

Adjustable fill switch activates an indicator and alarm. The fill switch does not shut off the mower deck so the operator can choose to finish a pass.

HEAVY-DUTY PTO CLUTCH

PTO clutch

PTO clutchThe PTO clutch is designed to operate through many on/off cycles.

RIO AND INTERLOCK SWITCHES PROMOTE SAFE OPERATION

RIO control

RIO controlMowing while backing up is strongly discouraged.

An operator who deems it necessary and chooses to keep the mower engaged while backing up, must bring the vehicle to a stop, then lift and hold the power take-off (PTO) switch in the reverse implement position as the reverse pedal is depressed slightly. The operator can then release the PTO switch and the mower will continue to operate.

This procedure must be repeated the next time the operator chooses to keep the mower (or other PTO-operated equipment) engaged while backing up.

INTERLOCK SWITCHES

Switch senses if hopper is installed

Switch senses if hopper is installedA switch senses if the hopper (or rear deflector option) is installed. If the hopper (or rear deflector option) is not installed and the PTO switch is actuated, the PTO will not operate.

A brake interlock switch is provided so the tractor will not start unless the brake is depressed or the parking brake set.

A tractor seat switch will turn off the PTO if the operator leaves the tractor seat; it will also shut down the engine if the park brake is not set and the operator leaves the seat.

Either the operator needs to be in the seat or the hopper or deflector need to be installed for the engine to run.

Frame is reliable heavy-duty welded steel

Heavy-duty frame

Heavy-duty frame Steel front side of hopper bolted to frame

Steel front side of hopper bolted to frameThe frame is made of heavy-formed and welded steel, reinforced in critical areas for even greater strength.

The steel front side of the hopper is bolted to the rear of the tractor frame:

- Reinforces the frame and provides a solid support for the hopper

- Frame formed from 12-gauge, 2.66-mm (0.105-in.) thick material

- Standard front bumper formed from 3.8-mm (0.15-in.) steel to complete the frame assembly

Standard rear hitch for tow-behind equipment

Standard rear hitch for tow-behind equipment

A standard rear hitch is included for pulling tow-behind equipment. Simply lift off the hopper and the hitch is ready to use.

FRONT AXLE AND WHEEL SPINDLES ARE HEAVY-DUTY

Cast-iron front axle

Cast-iron front axleFront axle is made of nodular cast iron:

- Cast-iron front axle is strong and shock resistant.

- Cast iron will not yield under heavy loads or impact.

Replaceable bushings are used at the front axle pivot and steering spindles of models with power steering:

- Bushings provide excellent wear resistance.

- Grease cavity between the bushings maintains lubrication and easy steering between greasings (X370).

- Grease fittings at each spindle are easy to service.

FRONT STEERING SPINDLES

Steering spindle

Steering spindleFront steering spindle diameter is 19 mm (0.75 in.) for strength and long life:

- Have strength to handle heavy implements

- Provide long life at bearing surfaces

- Use sealed, precision bearings in front wheels

Modern styling is eye appealing and functional

Attractive styling

Attractive styling Hood air-intake louvers

Hood air-intake louversSmooth, rounded contours present a modern, stylish appearance:

- Hood styling incorporates efficient full-length air-intake louvers on each side, rather than on the top, for cooler engine operation and lower operator station sound levels.

- Hot air is vented out the front grille, away from the operator.

- The fully enclosed hood is made of molded-in-color material.

- Reduces sound

- Will not rust or dent

- Distinctive grille and large, one-piece fender deck complete the styling package.

TWO HEADLIGHTS GIVE EXCELLENT VISIBILITY

Optimum lighting pattern

Optimum lighting pattern Headlight lens

Headlight lensHeadlights are standard equipment:

- Two 27-W bulbs provide excellent lighting for improved visibility during evening operation.

- A headlight position on the ignition switch makes it easy to operate the headlights.

- Headlights are designed to provide an optimum lighting pattern for mowing.

Operator station is comfortable and convenient

Comfortable operator station

Comfortable operator station Operator station

Operator stationThe operator station is designed for operator comfort and ease of using controls:

- A large, 36-cm (14-in.) diameter, steering wheel is comfortable to use and minimizes steering effort.

- Full-length foot mats provide comfort for the operator and protect the footrest area.

COMFORTABLE SEAT

Comfortable open-back seat

Comfortable open-back seatAn open-back, 38-cm (15-in.) high-back seat provides a comfortable, smooth ride and good support for the operator:

- Seat travel of 17 cm (6.6 in.) with 15 positions allows the operator to be seated comfortably and easily operate the controls.

- Seat can be easily adjusted fore and aft by the operator while sitting on the seat.

- Open-back design allows air circulation to keep the operator's back cool and dry for a more comfortable ride.

- Grasp at the top of the seat is conveniently located for use when tilting the seat up to protect it from the weather.

ADJUSTABLE SEAT SUSPENSION

Seat suspension with springs in rear position

Seat suspension with springs in rear position Seat suspension with springs in forward position

Seat suspension with springs in forward positionThe seat suspension is adjustable, without tools, for the weight of the operator:

- Springs are adjustable fore and aft to any of three positions.

- No tools required

- Allows fine tuning of the suspension for the operator's weight

- Back position for more support for heavier operators

- Tool tray is designed into the seat base.

- Can be used to store gloves, small tools, etc.

- Convenient storage location for Exact Adjust wrench and gauge

CUP HOLDER AND TOOLBOX

Cup holder and covered toolbox on fender

Cup holder and covered toolbox on fender Covered toolbox with open cover

Covered toolbox with open coverA cup holder and toolbox are located on the fender for operator convenience:

- The cup holder holds a variety of container sizes.

- Toolbox provides convenient storage.

- Cup holder and toolbox are constructed of durable acrylonitrile butadiene styrene (ABS) plastic.

12-VTFAST CONNECTOR

Fast connector location

Fast connector locationA mid-vehicle, 12-V fast connector, located under the tractor’s fuse box, is included as standard equipment to reduce initial installation time for some attachments that operate on 12-V power from the tractor:

- The four-cavity connector includes battery, ground, and key switch terminals and is turned on and off with the ignition switch.

Serviceability convenience is built in

HOPPER ADJUSTMENT AND REMOVAL

Adjustable hopper latch

Adjustable hopper latch Hopper is easily removed and reinstalled

Hopper is easily removed and reinstalledHopper latch is easily adjustable for operator preference and conditions:

- Spring can be located in any of three holes.

- More latching effort is required for hilly or rough operating conditions.

The hopper is easily removed by using the rear handle to raise the back end of the hopper 25 degrees, or about 13 cm (5 in.), and then using both handles to lift the hopper vertically out of the notches:

- No tools are required.

- There is nothing to disconnect.

Hopper removed

Hopper removed Chute shown pulled out part way

Chute shown pulled out part way Chute is easily removed and cleaned if necessary

Chute is easily removed and cleaned if necessaryThe chute can be easily pulled out and removed:

- Chute must be at least partially pulled out before removing the mower deck.

- Removing the chute makes cleaning easy.

EXACT ADJUST PORTS AND ONBOARD DECK-LEVELING GAUGE MAKE PRECISE DECK ADJUSTMENTS EASY

Deck-leveling gauge and hex adjusting tool stored under tractor seat

Deck-leveling gauge and hex adjusting tool stored under tractor seat Exact Adjust access holes

Exact Adjust access holesA mower deck must be level side to side and properly adjusted front to rear to give the best cutting performance. A removable, onboard deck-leveling gauge and a hex-key tool are provided to make adjustment easy:

- Gauge and hex-shaped tool conveniently located under the tractor seat in a special storage location.

- Exact Adjust leveling ports are provided on each side of the operator platform above the mower-level adjusting bolts. With the hex-shaped tool, they provide convenient access to allow quick and easy adjustment of the mower for the best quality of cut.

The Exact Adjust feature is standard on all Select Series™ X300 and X500 Tractors:

- There is no need to reach under the fender deck while making the mower-level adjustment.

- On-board deck-leveling gauge, Exact Adjust ports, and the hex tool work together.

- Level the mower deck side-to-side

- Set the correct amount of rake (front-to-back deck orientation)

- Calibrate the cutting height to the cut-height adjusting knob setting

- Exact Adjust simplifies leveling the mower deck if equipped with a Power Flow™ blower.

- To give the best cut, mower level should be adjusted if alternately mowing with and without blower installed. The Exact Adjust feature makes this easy.

Deck-leveling tool placed under deck

Deck-leveling tool placed under deck Using included ball-hex tool to level mower deck

Using included ball-hex tool to level mower deckConsult the operator's manual for the correct adjusting procedures for each tractor model. Basic adjusting steps to properly level the mower deck include:

- Park the tractor on a level surface.

- Inflate tires to the correct pressure.

- Consult the label for the cutting-height knob that is located on the console of the machine. This label shows deck-leveling position and location of deck-leveling adjustment points.

Cut height adjusting knob

Cut height adjusting knob- Set mower cutting-height knob to the correct deck-leveling position of 6.4 cm (2.5 in.)

- Adjust mower wheels as necessary so they do not contact the ground surface.

- Remove the onboard deck-leveling gauge that is located under the seat.

- Using the Exact Adjust ports and tool, adjust mower deck side-to-side level so the deck-leveling gauge just slips under the left and right lower deck rim at the designated adjustment points.

- Left-rear and right-rear adjustment points are under the deck rim near the corners of the deck.

- Adjust mower deck front-to-back level, if necessary.

- Loosen rear nuts equally on each side of front lift rod.

- Turn front nut equally on each side clockwise to raise front of mower or counterclockwise to lower it until gauge just slips under the front adjustment point.

- Front adjustment point is under the front center of the deck.

- Tighten rear nuts after adjustment is complete.

- Return the gauge to its storage position.